As the roads North of Paris begin to narrow and the vistas become both more picturesque and provincial, an architectural edifice sits imposingly at the edge of the Halatte forest in Oise. On approach, Les Ateliers de Verneuil-en-Halatte – where CHANEL’s iconic bags have been made for over 40 years – conveys the sense of intrigue we might expect to see in expressionist science fiction cinema: a concoction of monumentalism and modernism, a beguiling and impenetrable high security facility harbouring mystery and intelligence from within.

In stark opposition, the mood once within the doors of this awarded Enia Architects designed space – having achieved the highest certifications for optimised management of flows and exceptional environmental performance such as solar energy – is deeply harmonious: a sense of serenity permeating from the abundant swell of natural light.

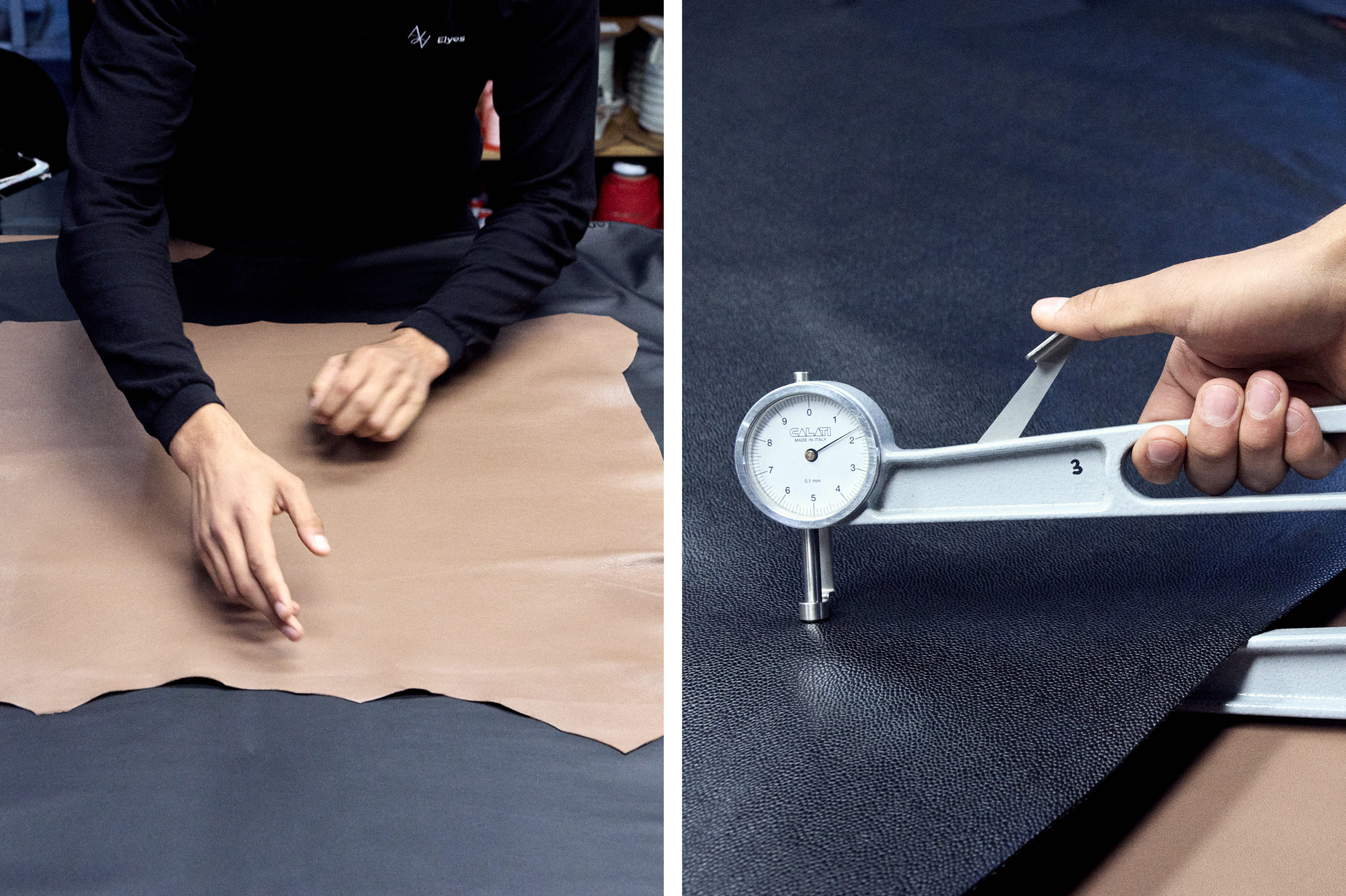

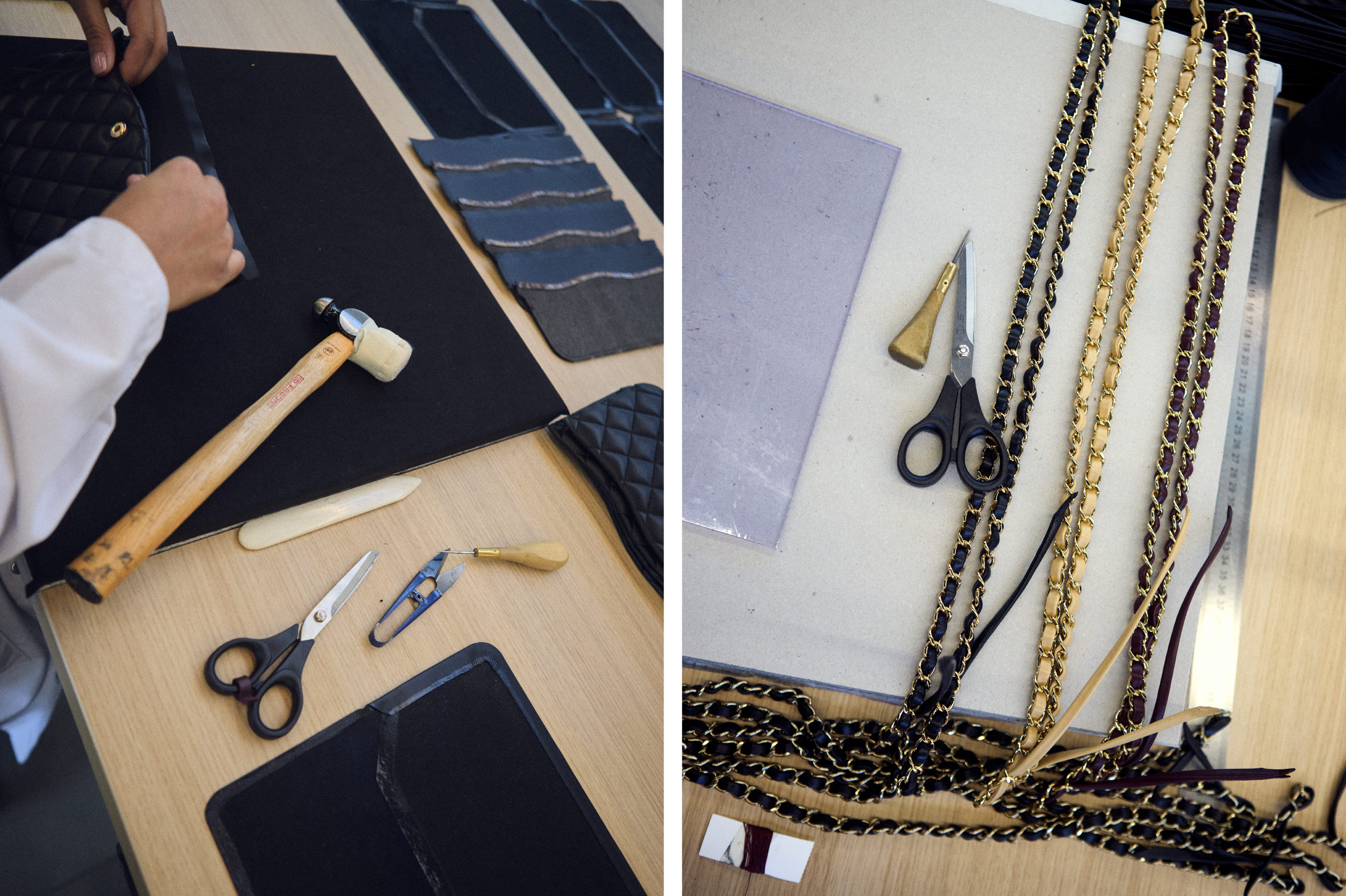

More like a biophilic laboratory than an expansive leather workshop, there’s a certain kind of poetry in motion to the defined order here. The ‘Ateliers de Verneuil’ logo – cursive and delicate in tone – graces the lobby and communal spaces along with the stealth monochromatic buttoned uniforms of the almost 500 large team who work from there. In the atrium, a giant screen broadcasts the recent runway shows, also a gathering space for the artisans to see their creations shown as a part of the CHANEL collection in real time. Within the vast workshops there is a distinct marriage of liberation and movement as artisans work with the unique savoir-faire, translating the vision of the Studio on Rue Cambon alongside the ritual gestures of that have been mastered since the inception of the 2.55. This precise choreography is a task that requires the expertise of some thirty artisans and takes around 180 steps to complete the making of one iconic bag, reflecting the mastery of techniques and craftsmanship involved.

"The process is exacting; each artisan or leatherworker has tools that become entirely personal to them – shaped by their hands and years of experience. Just as there are no phones or devices welcome in their work areas, rather a diary in which they are able to track their progress."

Until recently, Verneuil has been rarely opened, however, CHANEL’s President of Fashion, Bruno Pavlovsky, now feels it is important to raise the veil on this process of creation to convey the soul that lies within CHANEL’s classic bags. “We decided to open the doors because we wanted to show the amazing expertise, the outstanding quality of the materials required and the care that artisans put behind the 11.12 bag. We wanted to share the passion of all these people working on this unique product and show how important they are for the House,” he says.

“Opening the doors of Verneuil allows us to show how exceptional and sophisticated the 11.12 bag is, and to explain to our clients why it embodies the ultimate luxury and all the CHANEL values. The technique for this bag is unique and requires a specific expertise. We call it a couturière bag, because the manufacturing process is inspired by ready-to-wear (with the piqué-retourné stitching). It has been the same technique since the bag was created by Gabrielle Chanel 70 years ago in 1955, and in order for the artisans to perfectly master that specific technique and gesture, it takes at least four to five years of training.”

It is true that only when one meets those whose hands have constructed these bags and bears witness to the precision and repose with which they work, is the uniqueness truly understood.

The process is exacting; each artisan or leatherworker has tools that become entirely personal to them – shaped by their hands and years of experience. Just as there are no phones or devices welcome in their work areas, rather a diary in which they are able to track their progress. With dedicated presence some rely just on their hands, while those who work with machines – albeit seemingly quiet ones – seem to work in sympathy and total compatibility.

Perhaps what is most notable about the artisans we met is how they all spoke proudly of the emotion that lies within the pieces and materials, especially with regards to the leather and the craftsmanship such as the bridal stitch or the quilting inspired by the visual tone of the horse world so loved by Gabrielle Chanel herself.

“Verneuil has been operating for almost 40 years and is our very first manufacturer,” Pavlovsky shares to accentuate the myth. “It has been manufacturing the 11.12 for a long time and you saw the very special and specific techniques required to make this sophisticated and complicated bag, because it’s sewn and turned inside out. This bag is unique, there is no other bag in the world of luxury which is built this way. Some artisans have 10, 20, 30 and even over 40 years of experience and this is why they are so important to the House. They are important because they have the know-how, and they are able to transmit this know-how to the new generation. Our priority is to preserve this know-how through a system of apprenticeship, whereby experienced artisans work hand-in-hand with more recent recruits so that, over time, they learn how to master all these skills. To fully train one of our leather goods artisans takes around four to five years. The aim is for each artisan to eventually be able to make their bag from A to Z, but it’s a very gradual process,” he says.

“Some artisans have 10, 20, 30 and even over 40 years of experience and this is why they are so important to the House. They are important because they have the know-how, and they are able to transmit this know-how to the new generation.”

On the ground floor of Verneuil sits the academy known as Ateliers de Verneuil training school, which has successfully attracted a new generation of artisans, many of whom do not meet the stereotype of what we have come to know. Pavlovsky says they welcome “both newcomers on the job market and people seeking a career change.”

“The group has hired 1,200 people under the age of 30 per year since 2022. Verneuil-en-Halatte takes on between 40 and 50 artisans a year, mainly to replace those who have reached retirement age. As a result, a third of the workforce there is under the age of 30.”

This is important context, and certainly powerful storytelling at a time when the pricing of leathergoods and accessories right across luxury have been under the spotlight, a privilege Pavlovsky believes is crucial to preserving and protecting the integrity of the bags.

“Over the last few years, the cost of a bag has doubled, even tripled. If we compare ourselves to five years ago, we have seen a tremendous acceleration in the costs of the manufacturing process, the costs of raw materials, people, sustainability, traceability and transparency,” he says.

“At CHANEL, we have positioned our iconic bag at the top of the market and we need to protect it and keep its quality at the highest level. As it is an iconic bag, with all its values, sophistication and unique savoir-faire, its cost is not the same. Moreover, as you may know a few years ago we’ve applied a strategy of price harmonisation (to offer the same price everywhere to our clients), that is still a key engagement for CHANEL today. We consider it a matter of fairness.”

In keeping with transparency, while all materials used by CHANEL have long come from traceable supply chains, the European Union implementing new digital product passports will be a further opportunity for the bags to stand out. “All our materials come from supply chains that are traceable, sustainable and responsible. We work with tanneries in France, Italy and Spain that belong to our ecosystem,” shares Pavlovsky.

“The day the digital passport will be implemented, it will include mandatory information to calculate the carbon impact of each product, but it will probably also feature more marketing-oriented information about what makes the product and know-how specific.

The idea is not to do this for thousands of products, but to progressively enrich these digital passports for certain products with information that highlights the know-how that goes into them.”

“Our products embody the essence and values of our brand. This philosophy drives us to invest in the best creative processes, employ unparalleled craftsmanship, and select the finest materials. As mentioned before, the expertise required to craft an 11.12 bag demands four to five years of intensive training. Each bag is unique because the leather it is made of – as well as the craftsmanship involved in its creation – is unique. These quality requirements have not changed and remain as high as ever, and we feel it’s the right moment to highlight the magic behind each of our bags.”